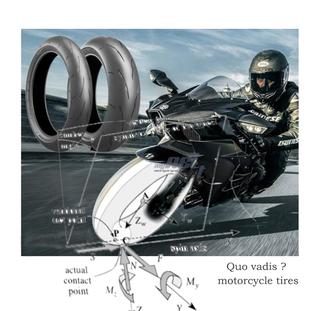

Motorcycle Tires Under Extreme Load: A Look at the Physics of Grip

This text dives into the extreme stresses placed on motorcycle tires at high speeds, highlighting the impressive performance of these seemingly simple components.

Forces at Play:

- < 200 HP: The engine's immense power needs to be transferred to the road through the tire, posing a huge challenge for grip.

- < 270 km/h (168 mph): At this speed, the tire rotates 1.5 times per second and travels 4.5 km (2.8 miles) further than the front tire due to "spin" caused by slippage.

- Torque: The engine's gearing amplifies torque at the rear wheel, resulting in strong pulling force.

- 1450 Newtons: This immense force pushes the motorcycle and rider through the wind, with the tire providing the frictional force necessary for forward movement.

- 150 kg (330 lbs) Wheel Load: The motorcycle's weight rests on the tire, further increasing friction and wear.

- 4.5% Slip: At high speeds, some slippage is unavoidable, leading to heat generation and wear.

- 100 Degrees Celsius Rubber Temperature: Frictional heat can significantly raise the rubber temperature, affecting its properties and grip.

- 270 Newtons Centrifugal Force: The centrifugal force on each individual belt thread within the tire is enormous and can lead to structural damage.

Fascinating Physics:

The phenomena described illustrate the complex physics at play during the interaction between tire and road under extreme stress. Friction, slippage, heat generation, and centrifugal force all play a central role.

Tire Development:

Tire manufacturers invest heavily in developing tires that can withstand these extreme loads. New materials, rubber compounds, and tread designs are constantly being improved to enhance the safety and performance of motorcycle tires.

Conclusion:

Motorcycle tires are high-tech products that need to function under extreme conditions. The engineers and developers who design these tires do an impressive job of ensuring the safety and riding enjoyment of motorcyclists.